AND

OFFSET

Digital and offset – we can do both!

__________________

For the production of packaging, printing is the essential first step, after which die-cutting and gluing take place. The advantage of offering both digital and offset printing comes from the setup times. For large print runs, people tend to use offset printing, as the costs for long runs are significantly lower than for digital printing. On the other hand, digital printing is more cost-effective for short runs. Offset printing delivers impressive results and is even possible with us in 7 colors.

DIFFERENCES FROM DIGITAL AND OFFSET PRINTING

Warehouse Management – Inquire now without obligation and scale easily!

Find out here about the dependencies of print run, substrate and inking.

Contact us and let us convince you of our experience and passion for printing.

Circulation

The one-time, fixed costs of creating, exposing and setting up the printing plates in offset printing are offset by the ongoing costs of electronic print image generation in digital printing. This means that longer runs are more suitable for offset printing than for digital printing. However, it is quite possible to print different print images, i.e. grades, for the same packaging form. You can count on us to stay on top of things while striving for the greatest possible time and cost efficiency. However, as soon as it comes to very short runs, samples and high flexibility, such as personalization, the decision in favor of digital printing is clear.

Substrate

For the production of packaging, we mainly process the fiberboard in the form of sheets. Depending on the press, different types of cardboard and material thicknesses can be processed. We will be happy to advise you on the right choice of material. You can also find more information in the chapter “Material”.

Colorfulness

The CMYK color space of the non-self-illuminating body colors is composed of the primary colors cyan, magenta, yellow (Yellow) and black (Key). Basically, all other printing inks can be mixed from these so-called process inks. This is the principle we use for our four-color digital printing. This makes us more flexible, as we avoid time-consuming and costly color changes. The printing inks are continuously available to our digital presses via lines.

In offset printing, on the other hand, new printing plates are used for each job and the associated inks are set up in the press. In addition to the process colors, we can print additionally or exclusively with so-called spot colors from the Pantone and HKS color systems. These color systems define color shades in a universally valid way so that they can be reproduced at any time without deviation. Since these are prescribed color mixtures, spot colors are more cost-intensive than CMYK process colors. However, spot colors promise more brilliant, fresher and consistent color results and your house colors can always be reproduced correctly. In total, our offset presses have seven inking units.

Regardless of the ink system, we use only certified, so-called food-safe printing inks for all types of packaging that come into direct or indirect contact with food.

You can find out which specific presses are available for your packaging printing in the “Machines” section.

PERFECT

IN

PACKAGING

Why Mass Customization is the Future in eCommerce

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputat

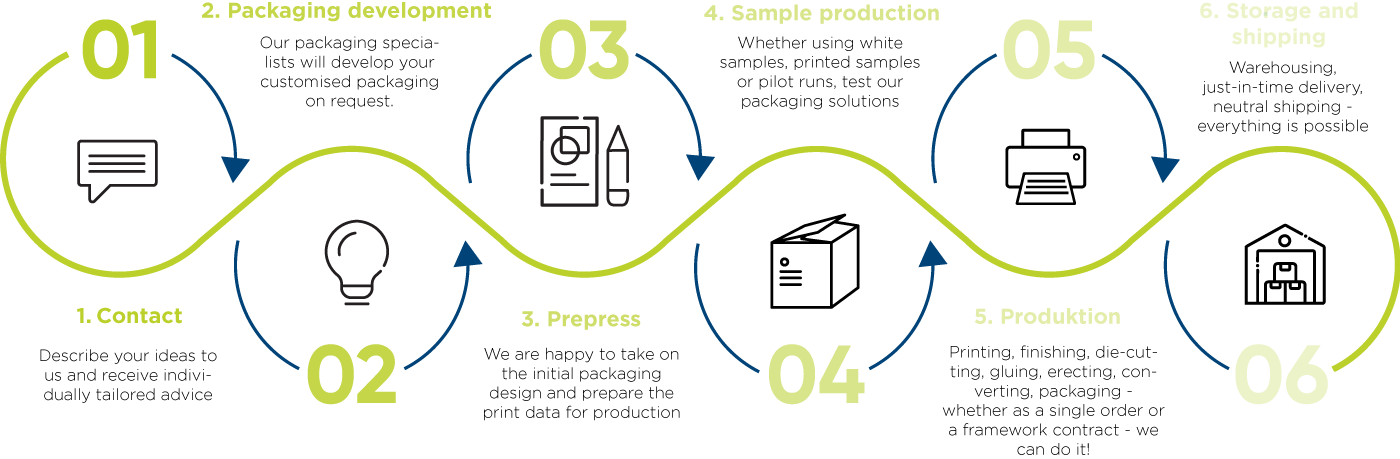

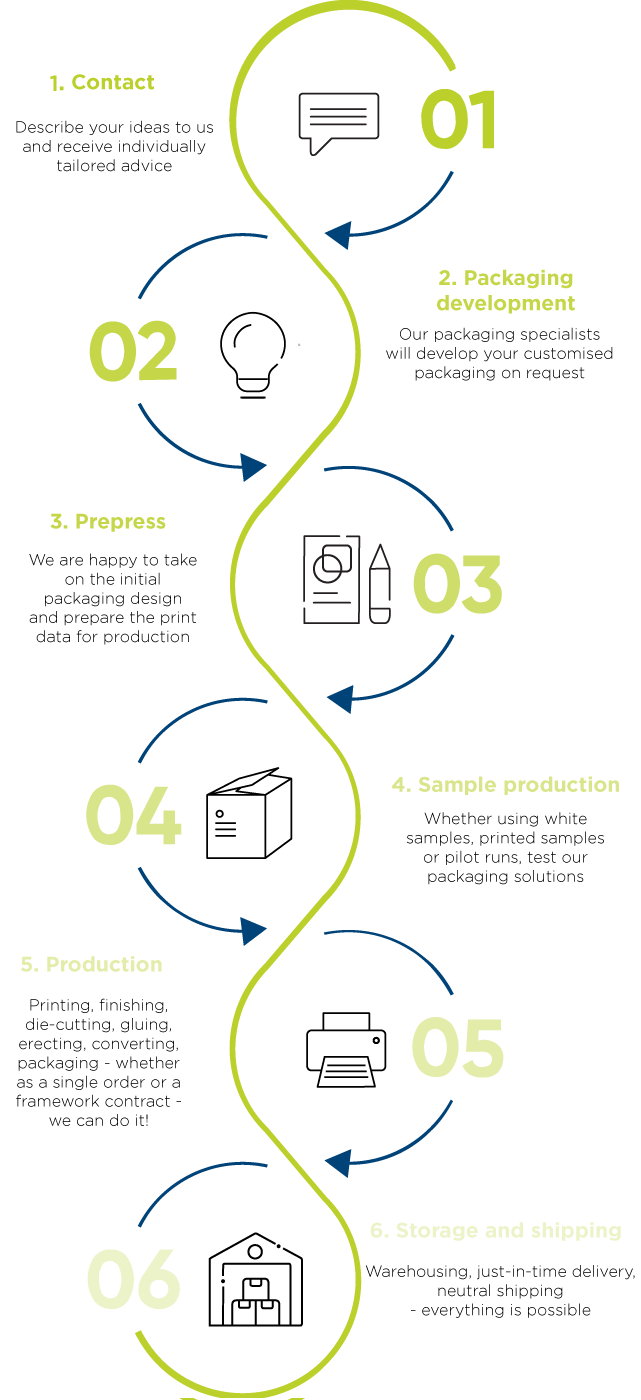

OUR PACKAGING SERVICE

From packaging development, through production to delivery

We support you exactly where you need our help.

Whether you already know exactly what packaging you need and may even have production-ready die-cut drawings, or you’re just starting out and looking for inspiration and technical advice, we’ll support you at every point of your journey between packaging development, production and storage, and delivery. In doing so, we draw on our many years of experience as a multifaceted print service provider without resting on our customers’ satisfaction. Our goal is to constantly face new challenges and develop customized solutions for our customers and their products. Contact us and let us convince you that we are your reliable partner.

How to – Frequently Asked Questions about Print on Demand

What is digital printing?

What is offset printing?

What role does printing play in packaging development?

What is the possible color in printing?

What kind of jobs are the printing processes suitable for?

360° SERVICE

Use our complete service from order management and production to shipping and logistics

A well-rounded project!

Packaging can come in many types and forms. Thanks to our wide range of machinery, we can produce a wide variety of packaging in large and small runs. But we offer not only the finished product. Our services also include white label shipping, packaging design support, custom finishing options and warehousing. Learn more here:

Whitelabel shipping

We ship your product in your name, in your own packaging if you wish, to over 165 countries worldwide.

PACKAGING DEVELOPMENT

Individual packaging ideas. We support you in the implementation of your idea.

Warehousing

Cleverly combined – our affiliated warehouse logistics perfectly round off your product and shipping offer.

Sample Production

You have a packaging idea, but don’t know if it works for your product? We produce both colored and white patterns.