PACK

YOUR

BRAND

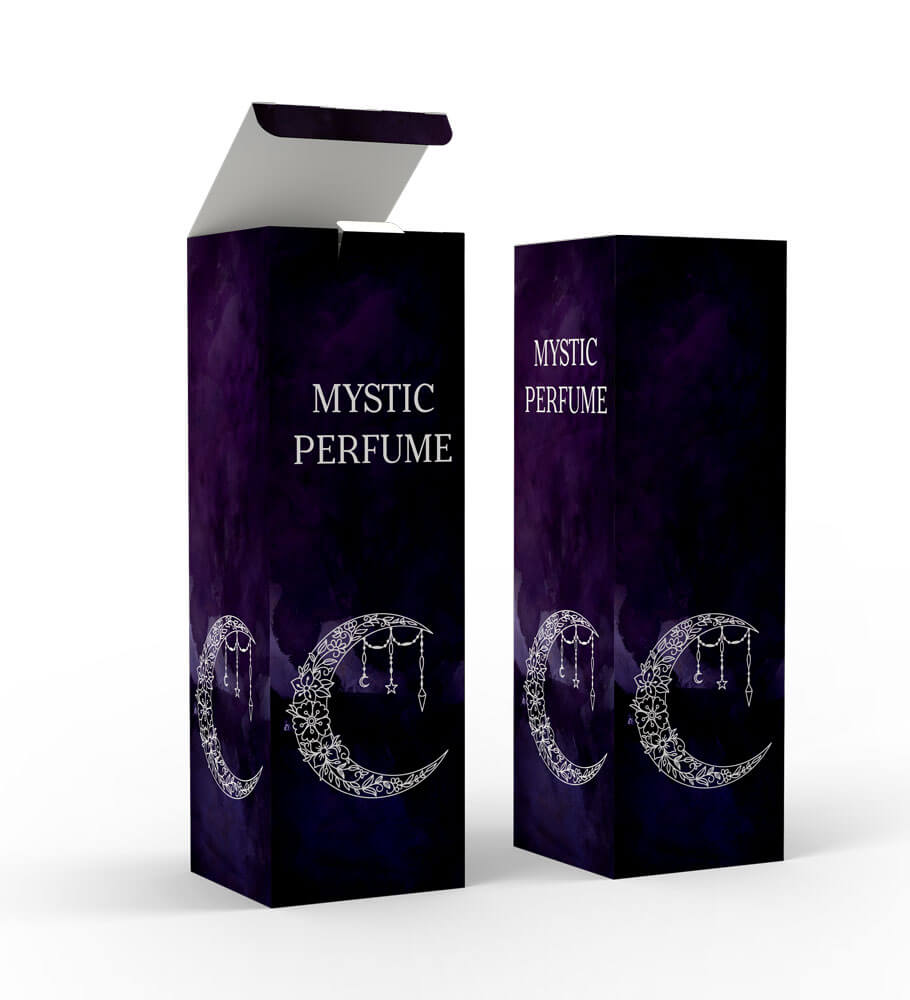

Product packaging –

Functional packaging that makes your brand shine

Packaging must mainly fulfill its product-specific functions. If these are basically guaranteed, the focus can be placed on the individual design in terms of shaping and material selection. These design options are not restricted for non-food packaging by the requirements of food law. The wider choice of materials, printing inks and finishes helps us to put your brand and its values in the ideal spotlight.

Product packaging at a glance

__________________

- Product packaging

- Product Worlds Product Packaging

- Product Gallery

- Our packaging process

Product packaging in all editions, high quality and impressive

Why we are the perfect contact for you

The variety of products from non-food sectors such as electronics, drugstore, clothing, toys, music, etc. is large. Just as extensive are the different demands that products place on their packaging and the options available to meet them. With all these complex issues and interdependencies, it is good to be able to rely on an experienced partner like us. We support you exactly where you need us. We can advise you on the right type of box, printing and finishing to let your brand shine. Together with you, we develop packaging that fits your product like a glove. And we can also produce your own packaging if you wish, with which you have already gained good experience. In large or small runs, always reliable, at eye level and to the point.

Let our packaging solutions and years of experience convince you.

PRODUCT COMPACTION PRODUCT PACKAGING

Individual product packaging that convinces

FOLDING BOXES

To produce your packaging, we mainly process the fiber material cardboard. Whether made from primary or secondary fibers, this material is ideally suited for processing into a wide variety of packaging solutions. Discover the world of folding cartons here.

In order for folding cartons to be produced, the flat sheet material is given a three-dimensional shape - consisting of base, body and lid - through targeted folding.

The clearly defined edges required for folding are created during the creasing process. The cardboard is deformed along the creasing lines into a kind of hinge. In the simplest case, the box body consists of four sides and an attached glue tab. During the gluing process, the fuselage is folded once and the glue tab is connected to the opposite side. We refer to this as longitudinal seam bonding.

Thanks to this simple principle, a wide variety of folding carton types can be created, all of which have the same characteristic: they are delivered lying flat and are not erected until they reach you in the filling line, either by machine or manually by hand. This saves an enormous amount of space during transport and simplifies further machine processing.

In the development of folding cartons, we are guided in the basis by the so-called ECMA code. The European Carton Makers Association (ECMA) classifies different folding carton main types.

The categories thereby define the different soil and closure types.

Soil types:

- Insertion closure (with or without locking)

- Plug-in bottom

- Automatic bottom / Folding bottom

Closure types:

- Z-click closure / click box

- Pillow box / Pillowbox

- Gable packing / House packing

- Box with integrated hanger

- Rosette closure

- Chute

Building on this, however, there are hardly any limits to creativity. Folding boxes do not always have to be cuboid-shaped with six sides. Our developer team is happy to take up your challenge.

HINGED LID BOXES

To produce your packaging, we mainly process the fiber material cardboard. Whether made from primary or secondary fibers, this material is ideally suited for processing into a wide variety of packaging solutions. Discover the world of hinged lid boxes here.

Hinged lid boxes can be constructed from one or more die-cut parts. In each case, we bring a flat cardboard sheet into a three-dimensional shape by deliberate folding along defined edges. These defined edges are created during the die cutting process during creasing. Unlike our longitudinal seam glued folding boxes, hinged lid boxes require more than just one glue joint. For this purpose, when the box is erected, the fuselage is created either from the bottom part or from the bottom and the lid equally. As the name of this package implies, the lid can be folded (over the bottom and hull).

Our range includes cardboard boxes and 6-point glues, which consist of a die-cut and are erected only at the filler. However, we also offer more elaborate hybrid solutions. These consist of an already erected base part (see telescope box) and a glued-on lid.

Based on this principle, however, there are hardly any limits to creativity.

Our developer team is happy to take up your challenge.

INVERTED BOXES

To produce your packaging, we mainly process the fiber material cardboard. Whether made from primary or secondary fibers, this material is ideally suited for processing into a wide variety of packaging solutions. Discover the world of slip lid boxes here.

Inverted cartons are actually folding cartons, but we still give them their own category because, unlike longitudinal seam gluing, they consist of at least two separate die-cut parts. Inverted trays always consist of a bottom and top part. Similar to the hinged-lid box, the body of the telescope boxes is created during the respective erection of the bottom and top parts. Or a third component, called a neck or collar, forms the fuselage.

In each case, we bring a flat cardboard sheet into a three-dimensional shape by deliberate folding along defined edges. These defined edges are created during the die cutting process during creasing.

As the name of the packaging suggests, you put the two components on top of each other to close the box. There are several variants for the construction of the two parts, which we present to you below. Different constructions can also be combined for the lower part and upper part respectively.

- Hollow edge box

- Carding box

- 4 point bonding

- Inverted box with collar

There are hardly any limits to creativity with this packaging solution either.

Our developer team is happy to take up your challenge.

PUNCHED BLANKS

To produce your packaging, we mainly process the fiber material cardboard. Whether made from primary or secondary fibers, this material is ideally suited for processing into a wide variety of packaging solutions. Discover the world of die-cuts here.

Die-cuts include all types of packaging and their components that are not glued. The range is correspondingly extensive.

On the one hand, this category includes complete packaging. This includes both cardboard packaging or plug-in solutions that can be erected manually without gluing, as well as packaging that is only glued automatically in your filling line.

Secondly, this category includes packaging components such as inserts that are used to support your product in the actual packaging. Backing cartons (with or without Euro perforation) for plastic blister packaging also belong to this category.

BANDEROLE

To produce your packaging, we mainly process the fiber material cardboard. Whether made from primary or secondary fibers, this material is ideally suited for processing into a wide variety of packaging solutions. Discover the world of banderoles and slipcases here.

Banderoles and slipcases, which are made of cardboard, basically belong to the folding boxes. To create them, the flat sheet material is folded into a three-dimensional shape by deliberate folding. A banderole, unlike classic folding boxes, consists only of the body and thus has two opposite, open sides. A slipcase, in turn, receives an additional closed side in addition to the hull and thus has greater inherent stability. The clearly defined edges required for folding are created during the creasing process. Afterwards, banderoles and slipcases are glued at least lengthwise (in contrast to plug-in solutions, see die-cut blanks) and delivered lying flat.

Both types of packaging are used more as secondary packaging. Banderoles, which are slid over the primary packaging, allow you to add variable information or designs to your main packaging with little material input. Slipcases can also provide greater stability and protection for your product. In addition to different types of closure of the bottom or back, for example, double the hull material can provide greater stability.

Contact us so that together we can find the right packaging solution for your product.

FOLDERS WITH FILLING HEIGHT

To produce your packaging, we mainly process the fiber material cardboard. Whether made from primary or secondary fibers, this material is ideally suited for processing into a wide variety of packaging solutions. Discover here the world of boxes or folders with filling height.

Unlike the slipcases described above, fill-height folders are not shipped lying flat. The three closed sides are already erected and firmly glued in the production plant.

This solution is suitable not only for classic document folders, but also as a slipcase with or without a flap for your product.

SPECIAL BONDING

To produce your packaging, we mainly process the fiber material cardboard. Whether made from primary or secondary fibers, this material is ideally suited for processing into a wide variety of packaging solutions.

Our claim is to always find the right solution for your packaging problem. If your promising product requires packaging or a process that is not part of our standard repertoire, our specialists from development, management and production will look for an independent solution. The solution can be to adapt the design to our technical capabilities or to rebuild or expand our machines and processes to meet your needs. In addition to machine solutions, we also offer manual bonding.

In order to find a customized packaging solution for you, we work in close coordination with you as our partner.

We look forward to generating the right solution for your project. Get in touch with us.

Product Worlds

Discover our diverse packaging solutions

We offer a wide range of packaging solutions for various applications. Please feel free to inform yourself here about these areas in general and our packaging solutions in particular.

PERFECT

IN

PACKAGING

Why Mass Customization is the Future in eCommerce

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputat

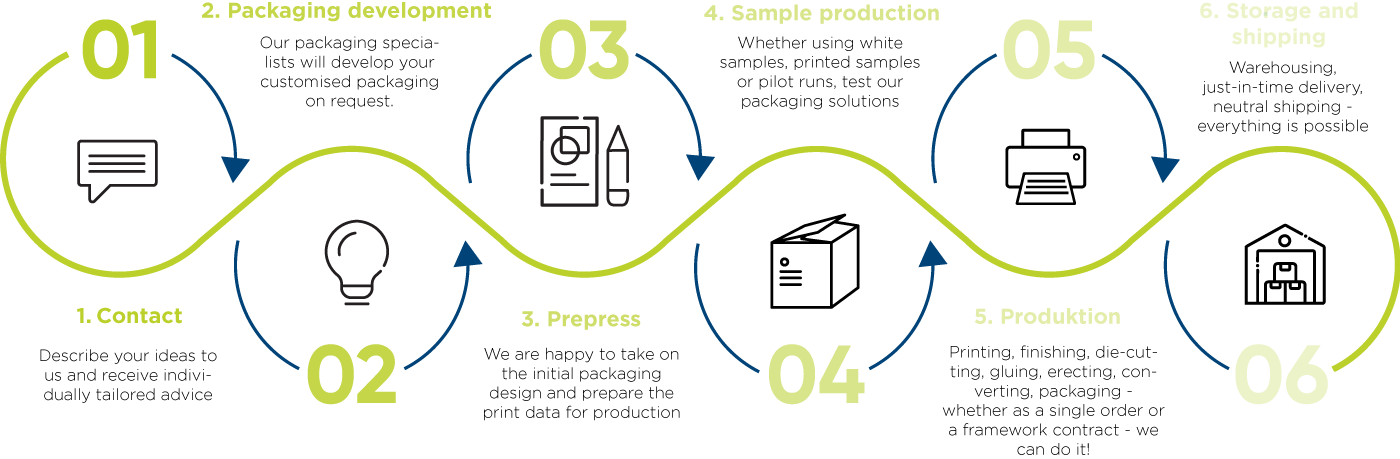

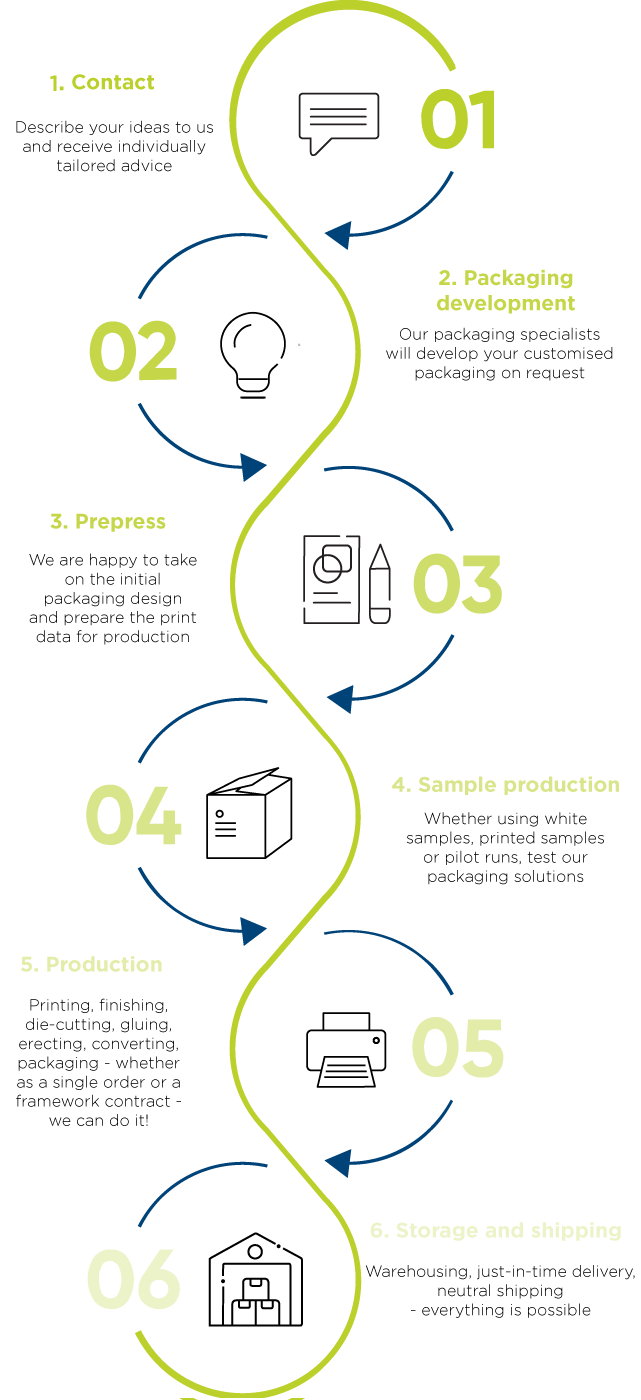

OUR PACKAGING SERVICE

From packaging development, through production to delivery

We support you exactly where you need our help.

Whether you already know exactly what packaging you need and may even have production-ready die-cut drawings, or you’re just starting out and looking for inspiration and technical advice, we’ll support you at every point of your journey between packaging development, production and storage, and delivery. In doing so, we draw on our many years of experience as a multifaceted print service provider without resting on our customers’ satisfaction. Our goal is to constantly face new challenges and develop customized solutions for our customers and their products. Contact us and let us convince you that we are your reliable partner.

How to – Frequently Asked Questions about Print on Demand

What types of product packaging can be produced?

What material is used?

What kind of bonding is possible?

What sizes can be implemented?

Are the product packages certified?

What printing methods are possible?

How are the packages developed?

How is the functionality of the packaging guaranteed?

PURE PRODUCTION POWER

Best quality with modern printing machines and brilliant finishing methods

Discover our wide range of print products – in short and long runs

Modern digital printing delivers cost efficiency, flexibility and outstanding results in the highest quality. Our entire production is ProcessStandard Digital (PSD) and according to the

BRC Global Standard for Food

and offers impressive possibilities in terms of high-performance printing technology, brilliant finishing methods and flexible finishing options. Convince yourself!